Custody Transfer & Metrology for Oil & Gas — Pro meter

Legal Shield • Engineering • Accredited Labs

Metrological Assurance and Legal Protection

OIL & GAS

Measurement Accuracy

Every ton of oil and every cubic meter of gas means money. We eliminate discrepancies.

Legal Protection

Documentation with full legal force. Acceptance certificates, protocols, and archives with digital signatures.

International Standards

OIML R117, API, ISO 17025, EN/GOST — a language recognized in any jurisdiction.

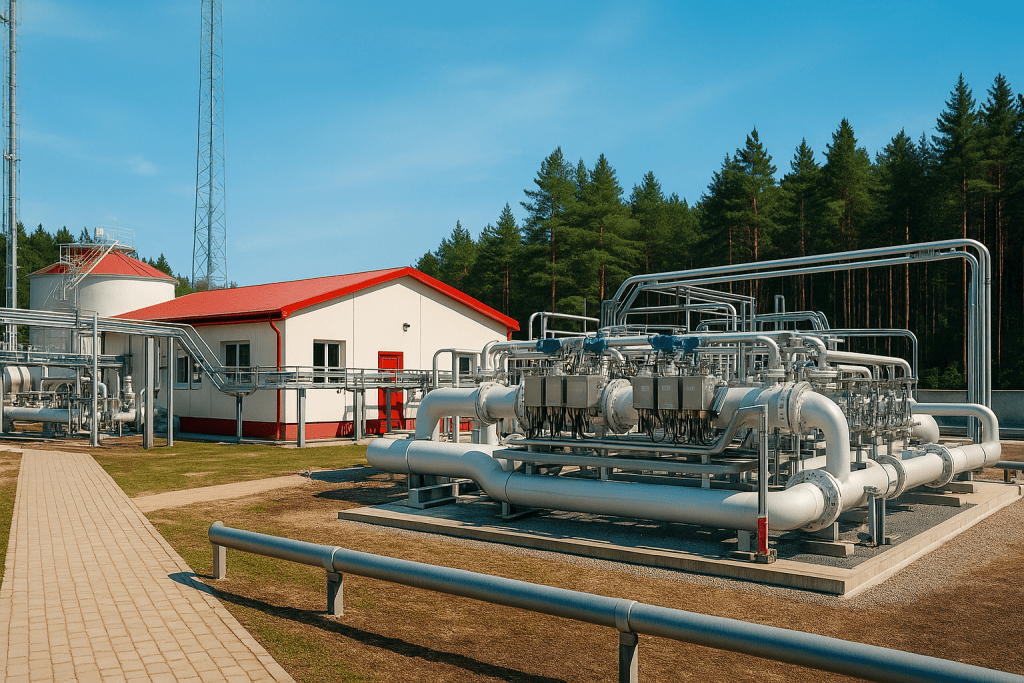

Custody Transfer — Secure and Transparent Operations

Metrological Assurance and Legal Protection

🛡️ Introduction

Custody Transfer is not just a technical measurement process, but a legally significant moment of transferring ownership rights over hydrocarbons. Every shipment of oil, petroleum products, or gas passing through terminals, pipelines, or ports is accompanied by financial settlements worth millions of dollars. Even minor discrepancies in the data can lead to legal disputes, fines, or reputational damage. Therefore, accuracy and transparency here become strategic factors, not merely engineering tasks.

-

⚖️

Foundation of trust. For the seller, buyer, operator, and state, correct and legally clean accounting is the basis for fair settlements and legal protection.

-

🧾

Legal validity. Every figure, act, and protocol carries evidential value and metrological justification.

-

📏

Standards and traceability. We operate under OIML R117, API, ISO, and GOST/EN, with full traceability to national and international standards.

-

🧠

The role of Pro meter. We integrate engineering and law so that measurements are objective and transactions are protected.

Pro meter views Custody Transfer as a mission: to ensure a process in which every figure, every act, and every protocol has legal force and metrological justification. We work at the intersection of engineering, law, and international standards (OIML R117, API, ISO, GOST/EN) so that customers can be confident — measurements are objective and transactions are safeguarded.

Thus, Custody Transfer is not a narrow technical topic, but a key element of transit corridors and global energy trade, where Pro meter acts as an independent guarantor of transparency.

Next: “Goals and Objectives”, “Pro meter Mission”, “Parameters and Principles”, “Implementation Stages”.

🎯 Goals and Objectives

The main goal of Custody Transfer is to ensure objective and independent accounting of the quantity and quality of hydrocarbons. Every ton of oil or cubic meter of gas represents money, tax revenues, and a strategic resource. Therefore, measurements must be not only technically accurate but also legally impeccable.

-

✅

Data reliability. Verified measuring instruments, approved methodologies, and international standards eliminate doubts and ensure that the data is defensible in court or arbitration.

-

🛡️

Risk reduction. Proper organization of the process minimizes legal and financial losses — even a 0.1% error at large volumes translates into millions.

-

🤝

Trust between parties. A transparent system, based on internationally recognized principles, eliminates grounds for endless disputes between seller, buyer, operator, and regulator.

-

🏗️

Long life cycle. This is infrastructure built for decades: design, construction, operation, and modernization. Pro meter supports the customer at every stage, shaping a culture of accuracy and responsibility.

Thus, the goals of Custody Transfer go far beyond measurement: they form the foundation of energy market sustainability and trust in transit corridors.

🌍 Pro meter Mission

“Without metrology, a project is legally incomplete.” — this is not a slogan, but the essence of Pro meter’s work. Our mission begins with the very first step — developing an accounting strategy and a roadmap for the future project. Already at the concept stage, we answer key questions: what will be measured, by what means, who the equipment suppliers are, which laboratories and test stands will be involved.

-

🗺️

Strategy and roadmap. We create a full accounting infrastructure — from tender documents to commissioning the system into industrial operation.

-

🤝

Virtual Metrology Center. We unite engineers, laboratories, metrology institutes, and the customer into a single ecosystem.

-

🔬

Comprehensive solutions. We develop accounting concepts, design measurement units, select equipment, and create methodologies and documentation.

-

🏛️

Legal protection. We ensure legal integrity at all stages: from tender procedures to arbitration documents.

Thus, the mission of Pro meter is to create a holistic concept of Custody Transfer. We design systems that guarantee fairness, transparency, and trust in commercial operations, which means — legal and economic sustainability of the project for decades to come.

Next section: “Custody Transfer Parameters and Principles”.

📐 Custody Transfer Parameters and Principles

Custody Transfer cannot be organized “in your own way.” This is a domain governed by strict international rules and principles. Compliance ensures the legal validity of measurements and protects the interests of all parties.

-

1️⃣

One batch — one measurement. Each shipment is recorded in a separate protocol, eliminating ambiguity and ensuring transparency.

-

2️⃣

Verified and certified measuring instruments. Commercial accounting cannot use equipment without a valid calibration certificate or certificate of conformity.

-

3️⃣

International standards. The foundation is OIML R117, API MPMS, ISO, as well as GOST/EN. This guarantees comparability and recognition of results.

-

4️⃣

Traceability. Every measurement must have a “chain of trust” — from the sensor to the national or international standard.

-

5️⃣

Legally binding documentation. Acceptance certificates, calibration protocols, and electronic archives with digital signatures serve as evidence in arbitration and courts.

These principles form the foundation of the entire Custody Transfer roadmap: from tendering and design to operation and auditing.

Next section: “Implementation Stages”.

⚙️ Implementation Stages

🧭 Stage 1. Strategy and Memorandum

Any Custody Transfer project begins with defining the parties: delivering and receiving, plus the regulator and the future Customer (joint venture). This step is often underestimated, yet it defines the entire subsequent roadmap.

In practice, everything starts with a protocol of intent or memorandum. It fixes key parameters: where the measurement point will be (seller or buyer side), which product is transferred, how financing is distributed, and who is responsible for the technical part.

For example, in one project in Latvia, the memorandum stipulated in advance that the metering unit would be built on the terminal side, while control measurements would be done in the VentMet laboratory. This avoided lengthy disputes already at the start.

Here Pro meter joins as an independent expert: we develop the accounting strategy, propose optimal schemes, and indicate which labs and which test stands will be required.

📑 Stage 2. Contractual Framework and Project

After the memorandum, the parties move to legal formalization. Tender documentation is prepared, specifying technical requirements for the metering unit: which instruments are acceptable, what accuracy must be achieved, which standards (OIML, API, ISO, EN/GOST) are mandatory.

Very often mistakes appear at this stage. For example, customers limit themselves to “minimum” requirements and later face equipment failing calibration. At Pro meter we always stress: the tender is the project’s foundation. That’s why preparing technical specifications and accuracy KPIs is highlighted as a separate service (see Engineering).

The next step is selecting the general designer and contractors. Pro meter acts as the link: we check their specifications, adjust ToRs, and point out risks. For example, in one pipeline operator project we avoided the purchase of unsuitable flowmeters by suggesting an alternative — Coriolis meters instead of turbine ones, which ensured stable winter operation.

Thus, already at the contract stage we minimize risks and create a roadmap designed to work for decades.

🔧 Stage 3. Engineering and Equipment

Once the legal base is ready, the project moves to the practical phase — engineering and equipment selection. The goal is not simply to choose the “best instruments” but to assemble a system that works in specific conditions: climate, product viscosity, and terminal or pipeline operations.

We select flowmeters — turbine, Coriolis, or ultrasonic — based on real needs. In one Baltic project, we replaced outdated turbine meters with Krohne ultrasonic ones, cutting maintenance costs and doubling accuracy.

Mandatory elements include provers (ball, compact, or master meters), samplers, flow computers (e.g., OMNI), and SCADA systems. Pro meter integrates these so that data is not only recorded but also legally valid.

We also take into account cybersecurity and redundancy: dual lines, backup servers, access control. This approach makes the metering unit a protected system ready for audits and inspections.

🏗️ Stage 4. Construction and Commissioning

Once the project is approved and equipment selected, the most visible stage begins — construction, installation, and commissioning. Here it is critical that every pipe, sensor, and cable matches the design solutions and standards.

We use checklists for acceptance of installed equipment: verifying cable routes, sensor labels, compliance with diagrams. This eliminates errors before launch. After installation comes commissioning — SAT/FAT tests, parameterization of flowmeters, configuration of flow computers and SCADA.

In a Ventspils terminal project, Pro meter insisted on an additional FAT before equipment shipment. This revealed a firmware issue with the corrector, avoiding costly downtime on site.

The final step is commissioning for industrial operation. At this stage, acts and protocols are signed, and primary calibration and certification are conducted. For the customer, this is when the system starts delivering — transparent, legally protected accounting (Custody Transfer).

🔄 Stage 5. Operation and Support

Launching the system is just the beginning. The longest stage is operation and support. The key is ensuring that the metering unit not only works but maintains accuracy and legal validity for decades.

Pro meter develops a full maintenance program for the customer: monthly checks, annual calibrations, “M-factor” control for Coriolis meters, software updates. We maintain digital archives: all protocols, calibration certificates, and engineer reports are stored electronically with digital signatures (see Publications).

In practice, there were cases where regulators found parties unable to provide complete measurement archives. We implemented automatic backup and cloud integration — such situations are now excluded.

An integral part of support is dispute resolution and arbitration. Pro meter acts as an independent expert: confirming methodology validity, recalculating data, and forming a “legally clean dossier” (Legal Shield). This assures customers that even in conflicts, their interests are protected.

🧪 Laboratories and Quality Control

🔬 The Role of Laboratories in Custody Transfer

In any Custody Transfer project, laboratories play a key role. They provide independent verification of product quality: density, viscosity, sulfur and water content. This data directly affects pricing and tax revenues.

Pro meter integrates the customer’s existing laboratories into the overall system or helps expand their scope of accreditation. If needed, we design new laboratories from scratch — from engineering to commissioning.

📊 Quality Control and Methodologies

Quality control includes both real-time measurements (inline sensors) and regular laboratory analyses. We develop methodologies that comply with international standards (ISO, ASTM, EN/GOST) and have full legal validity (Legal Shield).

Example: in one of the projects in Ventspils, the VentMet laboratory performed control analyses of every batch. This helped avoid disputes and reinforced trust between the parties.

📚 Documentation and Traceability

All laboratory test protocols are integrated into an electronic archive system with digital signatures. This ensures transparency and the possibility of verification at any time. We publish examples of methodologies and case studies in the Publications section.

Thus, laboratories are not just an “auxiliary part” but a full element of the Custody Transfer system, forming a legally protected basis for commercial settlements.

🕵️ Audit, Risks and Improvements

Before designing or modernizing metering units, we always start with an audit — this is point zero, an honest fact-check. Our task is to bring order to the data, see the real picture, and only then propose solutions. The result of Pro meter’s work is not just a “check mark,” but a condition report + prioritized recommendations (quick wins → mid-term → strategic) so that you immediately understand what to do today, what in a quarter, and what as part of modernization (see Legal Shield).

Confidentiality is absolute. All audit materials are delivered to the Customer only, in a single controlled copy (with copy marking and access log). If necessary, we work under NDA, using secure channels and digital signatures.

Audit formats:

- Remote (pre-audit): analysis of contracts, measurement archives, exports from flow computers/SCADA, laboratory protocols — gives a quick overview without business trips.

- On-site: inspection of metering units, piping schemes, sampling points, comparison of “as built” with design. Important: the scheme is arranged so as not to stop the process — we work in bypass windows, on duplicate channels, with agreed checklists.

Periodicity. Audits are needed not only “before a big project.” Operations are dynamic: modes, products, staff, and software change. We recommend periodic audits (e.g. every 12–18 months) for management to always know the actual condition, risks, and potential savings.

As part of the audit we form a risk register (technical, legal, cyber), and give specific steps for improvement: from reconfiguring a corrector and updating methodologies to expanding the accreditation scope of a partner laboratory and digitizing archives (see Publications). Pro meter always proposes feasible, cost-effective improvements — making decisions and achieving results easy.

📂 Case Studies and Practice

Pro meter’s experience in Custody Transfer includes projects in transit corridors of Latvia and the CIS. Among them — Ventamonjaks NH₃ Terminal, Ventspils Nafta, LatRosTrans — where we solved key tasks of organizing accurate and legally clean accounting. These projects show how Pro meter combines engineering, metrology, and legal protection in one solution.

It is important to understand: Pro meter is a well-known name not only in Latvia, but far beyond. Sometimes companies limit themselves to consultations without entering into contracts. This approach is like using a “free app”: you get a general idea, but not a complete result. The real value is revealed only when we are officially engaged — under a contract, where we truly leverage all our experience, knowledge, and most importantly, our connections: from state metrology institutes to major corporations and international laboratories.

It is only after signing a contract that customers see Pro meter’s participation give them a real advantage in tenders and projects. Our experience and methodologies help avoid mistakes, build regulator trust, and ultimately almost guarantee successful implementation.

Our approach is simple: we share knowledge generously, but always in a professional format — with clear obligations, transparent conditions, and results that carry legal weight. This is why leading transit corridor enterprises choose us: working with Pro meter is reliable, convenient, and beneficial.

🔬 Science and Development

Every Custody Transfer project brings not only practical benefits but also new knowledge that contributes to industry development. We never repeat projects exactly: each solution has an element of novelty that later becomes a standard solution for the whole industry.

Every project adds something new. Ideas tested today at one site become tomorrow’s mandatory requirements and practices of international standards.

The result is not only working metering units but also new research topics. Our projects regularly form the basis of theses and doctoral dissertations, and are used by universities and institutes as teaching examples (see Publications).

We are open to dialogue and ready to share such topics with the academic community. This makes Pro meter not only a solution integrator, but also a bridge between practice and science.

✅ Conclusion

Custody Transfer is the foundation of trust on which multimillion-dollar transactions, tax revenues, and company reputations rest. Any error in measurement turns into a business risk, which is why metrology here becomes a strategic tool, not just a technical function.

The mission of Pro meter is to build systems that work for decades: accurate, transparent, and legally protected. We can develop an accounting concept from scratch, organize cooperation with laboratories, expand accreditation scopes, design metering units, and support them in operation. Most importantly — we do it so that customers gain confidence and peace of mind: their interests are protected, their data recognized, their system working.

Today Pro meter means not only Latvia, but also international projects: from the Baltics to Africa. We are open to dialogue, ready to share experience, and help establish new metrology centers in transit corridors.

Pro meter — For Measurements!

📚 Standards and References

Below are the main international standards and guidelines forming the basis of Pro meter’s approach to Custody Transfer and metrology. For extended bibliography and application examples, see the Publications section and the legal dossier Legal Shield.

International Standards and Norms

- OIML OIML R117 — Dynamic measuring systems for liquids other than water (Custody Transfer).

- API API MPMS (Chapter 4 — Proving Systems; 5 — Metering; 8 — Sampling; 12 — Tanks; 21 — Flow Computer).

- ISO ISO/IEC 17025 — Competence of testing and calibration laboratories.

- ISO ISO 5167 — Measurement of fluid flow by means of pressure differential devices.

- ISO ISO 6976 / 6974 — Calculation of calorific value and composition of natural gas.

- EN/GOST Current harmonized EN/GOST for commercial metering and measuring instruments.

Guidelines, Methodologies, Benchmarks

- ASTM Methods for sampling and analysis of crude oil/petroleum products (D series).

- WELMEC / MID Recommendations on the application of European requirements for measuring systems.

- IEC IEC 61508/61511 — Functional safety (for I&C systems where applicable).

- Cyber Cybersecurity practices for flow-computers/SCADA (role-based model, logging, redundancy).

- Docs Forms of acts, protocols, and electronic archives with digital signatures — see examples.

Show extended list

- API MPMS Ch. 11 — Temperature/Pressure correction; Ch. 14 — Natural Gas Fluids Measurement.

- ISO 3171 / API 8.2 — Automatic Sampling of Petroleum Liquids.

- ISO 4259 — Statistical interpretation of test results (precision, bias).

- EN 12405 / EN 1434 — Gas measurement (volume correctors, heat meters) — where applicable.

- Guidelines of national metrology institutes (VNIIM, NMi, PTB, etc.) on calibration, proving, and traceability.

The full list of standards for a project is fixed in the contractual documentation (ToR, specifications, FAT/SAT plans). You can request a detailed bibliography for your facility here: Contact.